aluminium casting company QUALITY

Quality assurance

HOME > QUALITY > Quality assurance

Daeshin Metal is doing our best to supply high quality of

aluminum casting parts by inspecting casting/machining dimension and defects.

Daeshin Metal guarantees quality of parts by issuing test reports based on

customer’s requirement for raw material, tensil, hardness and casting sand by using various testing machine.

-

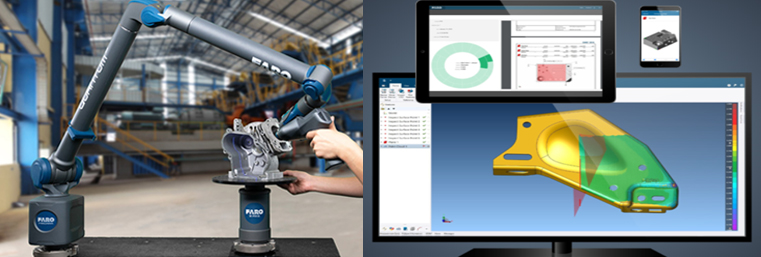

3D scanner

The dimensions and defects of finished parts are being verified by 3D scanner.Through intuitive comparison of 3D scanning data and CAD data, the errors can be checked immediately and quality data can be confirmed in advance. The analysis also allows the final inspection faster, so the quality inspection can be performed efficiently.

Scanning data is used effectively as method of communication with customers for design change and error check in development stage.

-

CMM machine

Machining dimensions are precisely measured by CMM machineDaeshin Metal guarantees quality of machined parts by issuing test reports based on customer’s requirement and provides high quality of parts by measuring precision inspection for machining dimension.